IBD/OBD Unit Manufacturers in Pune

IBD/OBD Unit Manufacturers, Suppliers, Dealers, Traders in Pune

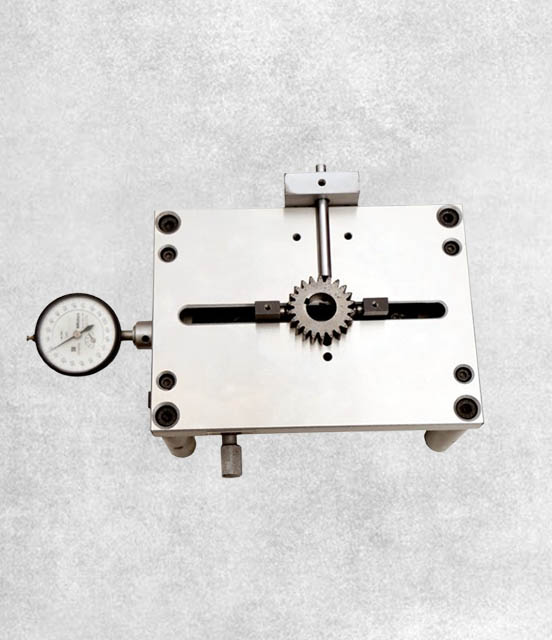

Sanket Enterprises stands out as the leading IBD/OBD Unit Manufacturers in Pune, IBD/OBD Unit Suppliers in Pune, IBD/OBD Unit Dealers in Pune, and IBD/OBD Unit Traders in Pune, specializing in high-accuracy bore gauge instruments that measure both internal (ID) and external (OD) diameters of cylindrical components. These IBD/OBD Units deliver tolerances as tight as ±0.001 mm to ±0.005 mm, ensuring reliable quality control in precision engineering. Widely used across automotive engine blocks, hydraulic cylinders, and aerospace components, they streamline inspection processes and enhance production efficiency. Backed by ISO-compliant manufacturing and over 30 years of metrology expertise, Sanket Enterprises’ IBD/OBD Units set the benchmark for accuracy and durability.

What Is an IBD/OBD Unit?

An IBD/OBD Unit is essentially a bore gauge—a collective term for tools that accurately measure the diameter of holes and shafts. Designed for both internal bore diameter (IBD) and external bore diameter (OBD) measurements, these units often integrate with micrometers, dial indicators, or digital readouts to provide direct, high-resolution readings.

IBD/OBD Manufacturers, Suppliers, Dealers, Traders in Pune, including Sanket Enterprises, produce IBD/OBD Units in various configurations—mechanical dial gauges, digital bore gauges, plunger-type gauges, and specialized taper gauges—to address the exacting demands of industries like automotive, aerospace, and heavy engineering.

IBD/OBD Unit Overview: Specifications, Types, Applications

IBD/OBD Unit Manufacturers in Pune supply instruments with measurement ranges typically spanning 10 mm to 500 mm, and digital resolutions down to 0.001 mm for unmatched precision. These units offer rapid Go/No-Go checks, reducing inspection cycle times and cutting defect rates in production by up to 20%. Additionally, compatibility with setting rings and master gauges simplifies calibration, ensuring consistent results day after day.

Specifications of the IBD/OBD Unit

| Specification | Details |

|---|---|

| Material | Hardened steel, tungsten carbide, ceramic |

| Accuracy Standard | ISO 286, JIS B 7420, ANSI B89.1 |

| Tolerance Range | ±0.001 mm to ±0.005 mm |

| Measurement Range | 10 mm to 500 mm |

| Resolution | 0.001 mm (digital), 0.01 mm (dial) |

| Contact Points | Steel anvils or carbide tips |

| Display Type | Mechanical dial indicator or digital readout |

| Calibration Temperature | 20 °C (standard) |

| Surface Finish | Ultra-smooth lapped finish |

| Wear Resistance | High durability, corrosion resistant |

Types of IBD/OBD Units

- Mechanical Dial Bore Gauge: Utilizes a mechanical dial indicator for direct readings; ideal for workshop inspections and general-purpose bore measurements.

- Digital Bore Gauge: Provides high-resolution digital readouts (0.001 mm), enhancing readability and reducing human error in critical applications.

- Dial Bore Gauge: A comparative instrument set to a nominal size via micrometer or ring gauge; measures deviation from nominal with high repeatability.

- Plunger Type Bore Gauge: Features a spring-loaded plunger mechanism for internal diameter checks; often paired with dial or digital indicators for versatile use.

- Taper Bore Gauge: Specifically designed for measuring tapered bores in applications such as valve seats and conical fittings.

Applications of IBD/OBD Units

- Precision Machining & Tool Making: Ensures components meet exact dimensional tolerances in CNC machining and die manufacturing operations.

- Automotive Component Inspection: Verifies the internal and external diameters of engine cylinders, pistons, and transmission parts to guarantee fit and performance.

- Aerospace Engineering & Defense: Measures critical bore dimensions in turbine engines, landing gears, and missile components where safety margins are minimal.

- Hydraulic & Pneumatic Systems: Checks bore sizes of cylinders and valves to prevent fluid leaks and ensure system integrity under high pressure.

- Bearing & Bushing Production: Validates bore diameters in bearing housings and bushings for smooth rotation and extended service life.

IBD/OBD Unit Ordering, Compliance & Safety Information

All IBD/OBD Units from Sanket Enterprises comply with ISO 286 tolerance grades and ANSI B89.1 standards, ensuring global interchangeability and reliability. Each unit is factory-calibrated at 20 °C, supplied with a certificate of compliance, and packaged to protect against transit damage. On-site maintenance and recalibration services are available to maintain peak performance.

Why Choose Sanket Enterprises?

- Unmatched precision with tolerances up to ±0.001 mm.

- Durable materials—hardened steel, carbide, and ceramic.

- Diverse product range—mechanical, digital, plunger, and taper gauges.

- ISO-compliant manufacturing and calibration.

- Over 30 years of expertise serving automotive, aerospace, and heavy engineering.

- Prompt on-site service, calibration, and technical support.

Ready to Elevate Your Inspection Accuracy?

Sanket Enterprises – IBD/OBD Unit Manufacturers in Pune | IBD/OBD Unit Suppliers in Pune. Partner with us to secure high-precision bore gauges that drive quality, efficiency, and peace of mind in your production processes. Contact us today to discuss your measurement needs.